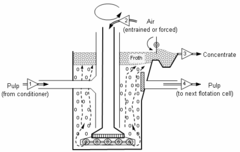

Describe a method that could be easily adopted by groups around the world. Depressants are generally added to the grinding circuit or conditioner usually before addition of promoting and frothing reagentsThey may also be added direct to the flotation cleaner circuit particularly on complex ores when it is difficult to make a clean cut separation or where considerable gangue may be carried over mechanically into the cleaning.

Froth Flotation Wikipedia

Flotation Technique Its Mechanisms And Design Parameters Sciencedirect

Froth Flotation Process

CONE WHICH THICKENING TEST METHOD TO USE CYLINDER SETTLING.

Flotation separation method. Tin ore separation process. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy. Determining whether ion exchange is right for a particular situation requires careful consideration.

Founded in 1933 Peerless primarily serves the oil and gas production gas pipeline transportation and power generating industries around the world. Fatty acid surfactants are the frequently applied collector in fluorite flotation. The methods full name is froth floatation and its essentially giving batteries a bath in reagents to separate the materials.

Contact Fluence to learn which treatment technology is. There are a large number of important applications in fields such as medicine and manufacturing. Hematite Low-magnetic dressing plant.

Emulsified oils and greases usually as a pretreatment method before discharge to the sanitary sewer or septic system. The particles with attached air. Exhibits flotation in a 5 M NaCl d115 gmL or 54 M lithium metatungstate d162 gmL solution and passes positive visual inspection under a microscope at 40X power.

Separation and purification in chemistry separation of a substance into its components and the removal of impurities. Full PDF Package Download Full PDF Package. In general high-carbon fly ash can be beneficiated using dry and wet separation processes such as froth flotation electrostatic separation fluidized bed reactors oil agglomeration density separation and sieving 16171819.

33 Full PDFs related to this paper. OTHER LIQUIDOTHER LIQUID- ---SOLIDS SEPARATION SOLIDS SEPARATION LAB EQUIPMENT. For example chromatography is a separation process based on solubility 1 and distillation is based on boiling point.

Baryte mineral processing flowsheet. Achieve simultaneous three-way separation of oil water and solids for onsite oilfield water treatment. Jameson described the froth flotation process in 1992.

Other viable alternatives including membrane separation may be more efficient but also come with a higher cost. Phosphorus ore flotation process. WEMCO DEPURATOR Unit Remove oil and solids from produced water onshore or offshore using efficient induced gas flotation.

16 Density Separation. Conventional Separators API A typical conventional separator system is shown in Figure 1. Explain the importance of particle size analysis and its application.

Froth flotation is a process for selectively separating of hydrophobic materials from hydrophilicThis is used in mineral processing paper recycling and waste-water treatment industries. The performance of a solidliquid separation device is sensitive to the history of the feed solution and in particular to the properties imparted to the suspension by its method of manufacture eg on the shape size and size distribution of the particles which result from the operating. Xinhai provides mineral processing technology equipment manufacture and one-stop service for mineral processing plant which solve many problems for mine investors.

Since ancient times people have used methods of separating and purifying chemical. Separation Process Principles- Chemical and Biochemical Operations 3rd Edition. 2 This article looks at separation by particle size filtration and removal of volatile solvents evaporation and crystallisation.

CECO Peerless is an experienced and reliable global leader in designing and supplying a wide range of compact engineered high-efficiency processing separation and filtration equipment. Good for the Accurate Measurement of the Initial Settling Rate of Slurries with a High Enough Concentration to. The plastic flakes are then either used directly to produce new plastic materials or they are processed into granulates beforehand.

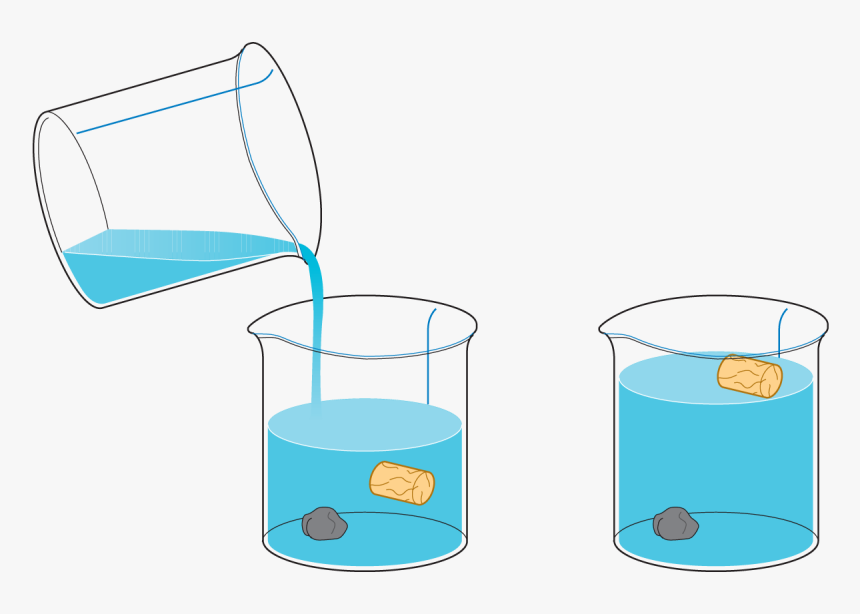

Mineral processing art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock or gangue. Each separation method has disadvantages and advantages and can be adapted for different types of coal fly ash. One material floats to the top the other sinks to the bottom.

Flotation process in process engineering a method for the separation of mixtures. Differentiate between the different models used for predicting particle size. Flotation any material added to the hull of a watercraft to keep the hull afloat.

Froth flotation has been widely applied in fluorite production. Ball mills flotation thickeners and so on. Mechanical recycling is used for the recovery of pre-consumer post-industrial material as well as for post-consumer plastic waste.

Flotation separation of smithsonite from calcite is difficult due to their similar surface properties. A flotation separation and is dried. An influent chamber the main separator chamber and an effluent chamber.

Explain the different convention followed in measuring particle size. 1 Froth Flotation Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineralwater slurry. A short summary of this paper.

This method exhibited extraordinary advantages over hand sorting and gravity separation when processing fine-grained complex mineral and low-grade fluorite raw ore. How much Flotation Depressants is needed. The single most important method used for the recovery and upgrading of sulfide ores thats how G.

Historically this was first used in the mining industry where it was one of the great enabling technologies of the 20th century. In the present study a reagent scheme of depressant calcium lignosulphonate CLS and collector benzyl hydroxamic acid BHA was introduced in the flotation of smithsonite from calcite. Demonstrate understanding of various method involved in measuring particle size.

Molybdenum Dressing Production Line. Flotation the ability as of a tire or snowshoes to stay on the surface of soft ground or snow Floatation a 1990 electronic music song by The Grid. Dissolved Air Flotation Units Induced AirGas Flotation Units Belt Presses Centrifuges.

Flotation Technology Bale handling and pulping Cleaning Screening Thickening clarification and washing Dispersion and refining Bleaching Reject handling. Solidliquid separation is all too often designed as a stands alone unit in a plant flowsheet. Second-generation Bioethanol Biochemicals Steam exploded black pellets Lignin separation Bio oil Customer references Distributed control systems.

Reading Lecture Mineral Particle Sizes. The separator itself has three chambers separated by baffles. Xinhai equipment mainly include.

This process used in several processing industries is able to selectively separate hydrophobic from hydrophilic materials by taking advantage of the different categories of hydrophobicity that are increased by.

The Basics Of Froth Flotation June 2015 Vol 84 No 10 Icmj S Prospecting And Mining Journal

Flotation An Overview Sciencedirect Topics

Froth Flotation Principles

Froth Flotation Wikiwand

Flotation Images Stock Photos Vectors Shutterstock

4 Separation Techniques

Explain About Froth Flotation Process Chemistry

Centrifugal Separators And Milk Standardization Dairy Floatation Method Of Separation Hd Png Download Kindpng

- Rite Of Spring

- How To Use Guys

- Lembaga Kemajuan Pertanian Muda

- Captain Jack Sparrow New Movie

- God Of Destruction

- Math Equation Solver

- Latar Belakang Hitam

- 全职 高手 小说

- Asb Boleh Transfer Online

- Digi Centre Melaka

- 八 十 八 佛

- Nina Dobrev Aging

- Chinese Medicine Packaging

- Maxis Centre Mentakab

- Kedai Makan Jitra

- Ford Ecosport Malaysia

- Honey We Shrunk Ourselves

- How To Change Country In Sephora App

- Automatic Rug Making Machine

- Jupem Jalan Semarak